Italy Bolsters Air Defense with U.S. Approval of High-Tech Missile Sales

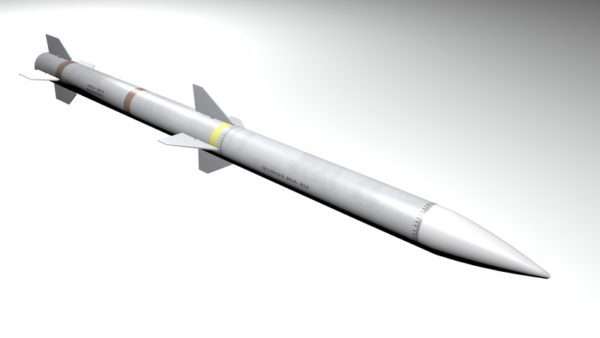

The State Department has reached a conclusion sanctioning a potential Foreign Military Sale to the Government of Italy for AIM-120C-8 Advanced Medium-Range Air-to-Air Missiles along with associated equipment, with an approximate cost of $69.3 million. The Defense Security Cooperation Agency has provided the necessary certification to inform Congress about this prospective sale today.

The Government of Italy has expressed a desire to procure twelve (12) AIM-120C-8 Advanced Medium-Range Air-to-Air Missiles (AMRAAM), which will augment a previous case that fell below the congressional notification threshold. The initial Foreign Military Sales (FMS) case, valued at $32.5 million ($23.0 million attributed to Major Defense Equipment (MDE)), encompassed twelve (12) AIM-120C-8 AMRAAM missiles. This notification encompasses a total of twenty-four (24) AIM-120C-8 AMRAAM missiles. Additionally included are Common Munitions Built-in-Test (BIT)/Reprogramming Equipment (CMBRE); ADU-891 Adaptor Group Test Set; AMRAAM storage containers and ancillary equipment; integration and testing support services; munitions support and supplementary tools; spare components, consumables, and accessories, along with repair and return assistance; contractor logistical aid; classified software distribution and support; and technical documentation, both classified and unclassified; studies and research; U.S. Government and contractor engineering, technical, and logistical assistance services; and other pertinent elements of logistics and program support. The estimated overall cost is $69.3 million.

This proposed sale will bolster the foreign policy aspirations and national security aims of the United States by enhancing the defense posture of a NATO Ally, which plays a significant role in political stability and economic development across Europe.

The suggested sale will enhance Italy’s ability to address current and emerging threats by ensuring the availability of modern, effective air-to-air munitions. Furthermore, it will promote interoperability between the United States, NATO, and the Italian Armed Forces. Italy already possesses AMRAAMs in its inventory and will seamlessly integrate this equipment into its military structure.

The proposed transfer of this equipment and support will not affect the fundamental military equilibrium in the region.

The primary contractor will be RTX Corporation, located in Arlington, VA. There are no known offset arrangements associated with this potential sale.

The execution of this proposed sale will not necessitate the assignment of any additional U.S. Government or contractor personnel to Italy.

There will be no negative implications for U.S. defense readiness as a result of this proposed transfer.

The outlined description and estimated monetary value pertain to the highest projected quantity and monetary figure based on preliminary requirements. The actual financial value may be lower based on final necessities, budgetary authority, and concluded sales agreements, if and when finalized.