Sophie’s Dynamic Support Strategies: Agile Excellence Unleashed

Thermal imaging solutions are loaded with intricate mechanics, finely adjusted optics, electronic elements, and various components that necessitate repair, replacement, or enhancement after a specified number of operational hours. To perform as effectively as on the initial day of use, they require upkeep by specialists — either armed forces personnel or professionals from the equipment manufacturer.

An adaptable repair and maintenance organization is crucial to operational readiness and a force’s capacity to execute its missions without the jeopardy of equipment malfunctions. Ultimately, the most effective solution is to engineer equipment to avoid failures in the first place.

For the latest Sophie series, Thales responded to insights from end users, optimizing everything from system architecture to component design to ensure exceptional reliability. The outcome today is the most dependable family of thermal imaging devices available. The Sophie Optima, for instance, features a 200% enhancement in MTBF (Mean Time Between Failures), indicating it malfunctions three times less frequently than earlier generations of cooled infrared cameras and is significantly more reliable than rival systems with similar range capabilities.

All in the family

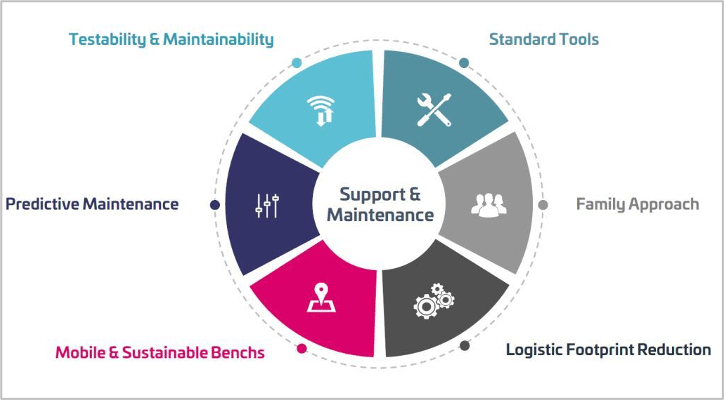

The new Sophie variants are also more manageable than other systems in the market. They possess 35% fewer spare parts required for intermediate maintenance when compared to competing products, and due to their design as an integrated family of systems, they share certain component references, facilitating easier management of replacement inventories. Most importantly, they were engineered from the beginning for enhanced reliability, testability, and maintainability, featuring rapid fault identification, convenient access to replaceable components, standardized connectors and tools, no manual preventive upkeep on detector coolers, and an overall configuration based on interchangeable blocks. This design drastically accelerates repairs and maintenance, significantly lowering equipment downtime.

Sophie Optima: reduced through-life expenses within a new lineage

Scalable, sustainable maintenance

The last thing field operatives desire is to carry around excessive equipment — as a traditional intermediate maintenance bench for optronic gear can be quite heavy. For the Sophie series, Thales is innovating a new concept for deployable maintenance tools for projected forces and rear bases. The entire setup can be transported in Pelicase© cases and weighs less than 75 kg, promoting a leaner and more agile unit, while significantly minimizing the logistical footprint of the force.

An upgrade pathway is accessible for clients who have previously acquired maintenance tools from earlier Sophie generations, ensuring the protection of their investments over time.

Integrated logistics management

To enhance repairs and maintenance for Sophie thermal imagers, Thales’s logistics management and predictive maintenance systems can be seamlessly integrated with the customer’s own ordering and HUMS information frameworks. This integration facilitates smoother and more dependable information flows, enabling real-time fleet management, streamlined administration, and notably shorter turnaround times for repair and maintenance tasks.

Transfer of maintenance

When clients seek greater autonomy, Thales can also facilitate a transfer of maintenance, delivering training, spare parts, technical support, and the appropriate workstations to sustain the fleet locally within the client’s maintenance facilities or with a local partner. For both general and specific maintenance tasks, clients can consistently rely on Thales repair workshops located near the production line in Elancourt, France, where products will be managed directly by our logistics support engineers and repair experts.